- Home

- Products

- Wire Drawing Machines

- Intermediate Copper Wire Drawing Machine

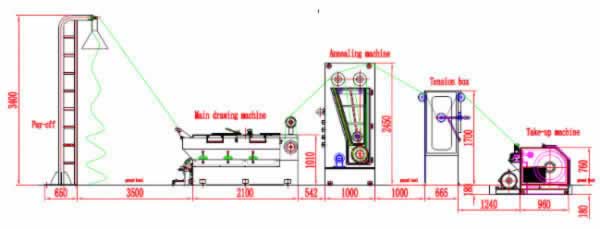

Intermediate Copper Wire Drawing Machine

Usage

The intermediate copper wire drawing machine has been carefully engineered for drawing copper wires from a maximum diameter of 3.5mm into wires possessing a minimum diameter of up to 0.4mm.

Main Features

1. Double inverter auto tension control system.

2. Unified 250 cast-iron main frame for maximum wire drawing precision.

3. Capstan treated with wear-resistant tungsten.

4. Suitable for continuous annealing.

| Machine Type | |||||||

| Max. Inlet Dia.(mm) | Ф 3.5 | ||||||

| Outlet Dia. ( mm ) | Ф 0.65~ Ф 2.8 | Ф 1.2~ Ф 2.8 | Ф 0.65~ Ф 1.60 | Ф 0.4~ Ф 1.6 | Ф 0.4~ Ф 1.5 | Ф 0.4~ Ф 1.2 | |

| Max. Die No. | 13 | 9 | 13 | 17 | 17 | 17 | |

| Max. Line speed (M/Min ) | 2000 | 1200 | 1800 | 1800 | 1500 | 1200 | |

| Body structure | Ironed cast | ||||||

| Slip Ratio of Machine | 20% | 18% | 20% | 20% | 18% | 18% | |

| Fix Speed Capstan Dia.(mm) | 280 | 300 | 250 | 250 | 260 | ||

| Transmission Type | By high precision grinding gear | By Chain | |||||

| Main Motor Power (KW) | 55 (45) | 37 | |||||

| Take-Up Motor Power (KW) | 11 (15) | 11 | |||||

| Lubrication Type | Full Immersion | Spray type | |||||

| Take-Up Bobbin Size (mm) | Φ 500/ Φ 630 ( Bore is Φ 127mm) or changed by requirement | ||||||

| Optional Equipment | 1. Continuous annealing device | ||||||

| 2. Coiler | |||||||

| On-Line Continuous Annealing Device | |||||||

| Type | 350T | 250T/B | 250T/A | ||||

| Machine Structure | horizontal | vertical | vertical | ||||

| Annealing Wheel Dia. (mm) | Ф 350 | Ф 250 | Ф 250 | ||||

| Annealing Wire Dia. (mm) | Ф 0.8~ Ф 2.8 | Ф 0.6~ Ф 2.2 | Ф 0.4~ Ф 1.2 (Ф 0.4~ Ф 1.6 ) | ||||

| Annealing Protection Type | steam or nitrogen | ||||||

| Annealing Voltage (DC) | 0~65V | 0~60V | |||||

| Annealing Current (DC) | 0~2500A | 0~(2000A . 1500A . 1200A) |

|||||

An intermediate copper wire drawing machine is a type of machine used in the process of manufacturing copper wires. It is typically used after the initial copper rod breakdown process, where copper rods are drawn down into smaller diameter sizes. The intermediate drawing process further reduces the diameter of the wire to a more precise size before it goes through the final drawing process. The intermediate copper wire drawing machine consists of several drawing dies through which the wire is passed, each die reducing the diameter of the wire slightly. The machine is designed to produce wires of consistent size and shape, with minimal defects or imperfections. The wire produced by the intermediate copper wire drawing machine is typically used in a wide range of applications, including electrical wiring, telecommunications cables, and electronic devices. By using an intermediate drawing process, manufacturers can produce high-quality copper wire that meets the specific requirements of their customers.